Key Figure in Bringing the Industrial Revolution to That Country

During the same timeframe that members of the Grimshaw family were actively participating* in the beginnings of the Industrial Revolution in England, Nicholas Grimshaw played a pivotal role in bringing the textile industry to Ireland. Nicholas was from Blackburn and apparently emigrated to Ireland in about 1776. He initiated the textile industry when he opened the first cotton mill in 1784 at a location near Belfast.

Nicholas and Mary (Wrigley) Grimshaw's family line (the "Irish" Grimshaw line) is described on a companion webpage.

*See companion webpages on Grimshaw connections to Hargreaves, Arkwright and Cartwright, whose textiles-related inventions were key to development of the Industrial Revolution.

William Grimshaw's Description of Nicholas' Introduction of the Textile Industry to Ireland

Additional Background on the Role of Grimshaws in Development of the Irish Textile Industry

Early Map of Whitehouse Area, Showing Cotton Mill

Potential Role of Nicholas Grimshaw's Father, Nicholas, in Textile Industry

| Webpage Credit |

Thanks go to Hilary Tulloch for providing most of the transcribed articles that appear on this webpage.

| William Grimshaw's Description of Nicholas' Introduction of the Textile Industry to Ireland |

(Note: this section also appears in the companion webpage on the Irish Grimshaw family line.)

William, the sixth (fifth surviving childhood) son of Nicholas, emigrated from Ireland to America in 1815, where he became a noted historical author (as described on a companion webpage.) He described the role of his father in the first chapter of his small book, "Incidents Recalled1" (1848, p. 9-10):

My father, the late Nicholas Grimshaw, being the first that introduced the spinning of cotton twist into Ireland, besides being a person of liberal education, and great public spirit, seems to have been a leading character, in his neighbourhood, from nearly his earliest settlement in the country. He was a native of Blackburn, in Lancashire, the birth-place of the late Sir Robert Peel; who, I have understood, was a near relation of my father’s; and I know we have, in our family, the same Christian names as the Peels, viz. Thomas, Edmund, William, and Robert. My father and Mr. Peel were nearly of the same age, and commenced business about the same time; but they were of very different dispositions; the former being fond of improving his property, by the planting of trees, and other ornaments, and also passing his summers at the fashionable watering-places in England; incurring an expense, not altogether warranted in a manufacturer, having fourteen children to support. He was also unremittingly attentive to the interests of the public; to which, Mr. Peel, being a man of much less education than my father was, in the early part of his career, but very slightly devoted.

The late Nicholas Grimshaw, who filled the office of mayor of the city of Preston, for more than forty consecutive years; and also the late Henry Fielding, of Garstang; were first cousins of my father’s. Our name is pure Anglo-Saxon, signifying "a dark wood;" and there is a dilapidated village, in Lancashire, in ancient times the residence of our family, from which it is derived.

My father came to Ireland, as I can collect from the births registered in the family Bible, about the year 1776, shortly after the improved system of spinning cotton-twist, the invention of which seems, with justice, partly to be attributed to Richard (afterwards Sir Richard) Arkwright, had been brought to some degree of efficiency, if not of perfection. His motive for settling in Ireland seems to have been two-fold, - first to evade the operation of Arkwright’s patent, (which did not, at any time, extend to Ireland,) and secondly, to reap advantage from the comparatively low rate of wages in that country. But in both these objects, he had evidently miscalculated. The advantage derived from the non-payment for the patent-right, was more than counterbalanced by the isolated position in which he placed himself, with regard to the obtaining of machinery, and the speedy adoption of new improvements; and the difference of wages was equally countervailed, by the waste and expense attending the instruction and training of raw hands. The consequence was, that, although the profits were considerable, owing to the infancy of the business, and the small competition, yet, in the course of time, he found himself constrained to apply to the Irish Parliament, for protection, in the nature of what is now called a tariff, amounting to ten per cent, upon cotton-twist; and, subsequently, when he commenced the printing of calicoes, in which he became highly distinguished for his taste and the permanency of his colours, he induced the parliament to impose a protective duty, also, on the latter article, amounting to more than one shilling per square yard; duties, which, it will appear, in the sequel, contributed rather to retard, than to accelerate the extension and perfection of the cotton manufacture, in Ireland.

My father’s first place of settlement was in the parish of Belfast, county of Antrim, about three miles north of that town, and five from the ancient, but poverty-stricken city, of Carrickfergus, on the site of an old linen bleach-green, or flax-mill, called Greencastle; where the writer of this memoir was born. In a small building, still in existence, near the high-road, and the sea-shore, at a landing-place, known as the Lime-stones, was erected the first machinery for spinning cotton-twist in Ireland. The machine being circular, and kept in motion both day and night, realized, in the first year, the enormous sum of eighteen hundred pounds, or eight thousand dollars. The water, however, at Greencastle, being found insufficient for an extensive business, my father purchased another site, adjoining, and further to the north, situated in the parish of Carnmoney; upon which, is since erected the beautiful and extensive village of Whitehouse, still the property of my family, with more than three hundred dwelling-houses, and having appurtenant one hundred and seventy English acres of good land, surrounded by a plantation of trees, with other rural improvements; in which, my brothers take great delight.

At Whitehouse, in conjunction with Mr. Nathaniel Wilson, a gentleman of some enterprise and capital, a new cotton-mill was erected, in 1785, capable of holding four thousand spindles and preparation; and, about ten years afterwards, by the enlargement of an old building, originally used for bleaching lawns, by a lady, named Tomb, another mill was organized, containing about an equal number of spindles; which was the greatest extent ever ventured on by any of the family; and these two mills, about twelve years ago, were converted to the purpose of spinning flax; the spinning of cotton in Ireland, having become almost wholly unprofitable, owing to the gigantic competition in Great Britain.

Belfast, which, at the time my father settled in its neighbourhood, contained only about ten thousand inhabitants, now reckons, at both sides of the Lagan, in the counties of Antrim and Down, not less than one hundred thousand.

| Additional Background on the Role of Grimshaws in Development of the Irish Textile Industry |

Clarke2 (1938, p. 213-215) provides additional historical information on the early development of the textile industry in Ireland:

…The linen trade also suffered in the closing years of the century from the competition of the cotton trade. The rise of this industry is closely associated with our parish and is connected with the name of Nicholas Grimshaw, who established the first mill for spinning cotton -twist at Whitehouse. "To the practical knowledge, genious and industry of this gentleman this country stands very highly indebted (Dubourdieu)

Grimshaw came to Whitehouse from Lancashire about 1760. He was accompanied by his father, also Nicholas Grimshaw, who was buried in our churchyard in 1775. The older Grimshaw was apparently interested in linen for in 1762, Magee printed a book for him on bleaching. His son, "the father of the cotton trade" was probably a man of small capital and his first venture at spinning was taken at the Belfast Poor House. Here Henry Joy and Thomas McCabe had a cotton spinning machine made at their own expense under Grimshaw's direction in 1777. The main motive of the undertaking was to give employment to the children in the Institution, and for some years the young people produced gloves, stockings and other articles. In 1784 Grimshaw, in partnership with Nathaniel Wilson, built at Whitehouse the first Irish mill for spinning twist by water-power, and the cotton industry was soon firmly established in Co. Antrim. The firm also specialized in calico printing and was noted for the style and elegance of its goods. In 1800 Grimshaw estimated that the cotton industry was giving employment to 13,000 people, and indirect employment to 14,000 others within a distance of twelve miles of Belfast.

Grimshaw acquired the townland of Ballygolan from the Marquess of Donegall together with the water rights in the Glas-na-Braddon. He lived at Longwood and built several houses for his sons: -- Glas-na-Braddon, Ballygolan Lodge and Frogmore. He also planted the Long Wood and built much of Upper Whitehouse.

He had seven sons and two daughters, most of whom remained in the district and engaged in linen and cotton manufacture. It is said that on the usual Bank holiday fete on the Cave Hill in 1840 no less than forty Grimshaws were present. This "Ulster Father" died in 1895 and was buried in our churchyard.

Boyle3 (1839, p. 51) provides additional insight into the influence of the Grimshaws on the introduction and development of cotton textiles in Ireland:

In 1786 the first cotton manufactory in Ireland was established in the adjoining parish of Shankill and on the verge of this parish, by the late Nicholas Grimshaw Esquire, who had previously come from England and settled in this parish. He soon after established the very extensive cotton printing and spinning manufactories which had until the year 1834 been carried on by his sons, and was the first to establish in this country a trade in which so much capital from this county has been embarked. The introduction of the cotton trade into Carnmoney laid the foundation of the great improvement which it has since undergone. The extensive employment the manufactories afforded not merely occupies the few unemployed labouring people in this, but attracted numbers from the surrounding parishes to such a degree that the populous villages of Whitehouse Upper and Whiteabbey are to them indebted for their origin and erection. The wages then given to printers and others were most liberal. The consumption of provisions and farm produce was of course materially increased, capital was more freely circulated in the parish and a stimulus was given to agriculture in consequence of the increased consumption of fan-n produce. Several other manufactories were established soon after in the parish, but of these there is now but one engaged in the printing business.

Longfield4 (1821) published extensive information on Nicholas Grimshaw and his role in development of the textile industry in Ireland. This text is quite lengthy and is provided at the bottom of this webpage.

| Early Map of Whitehouse Area, Showing Cotton Mill |

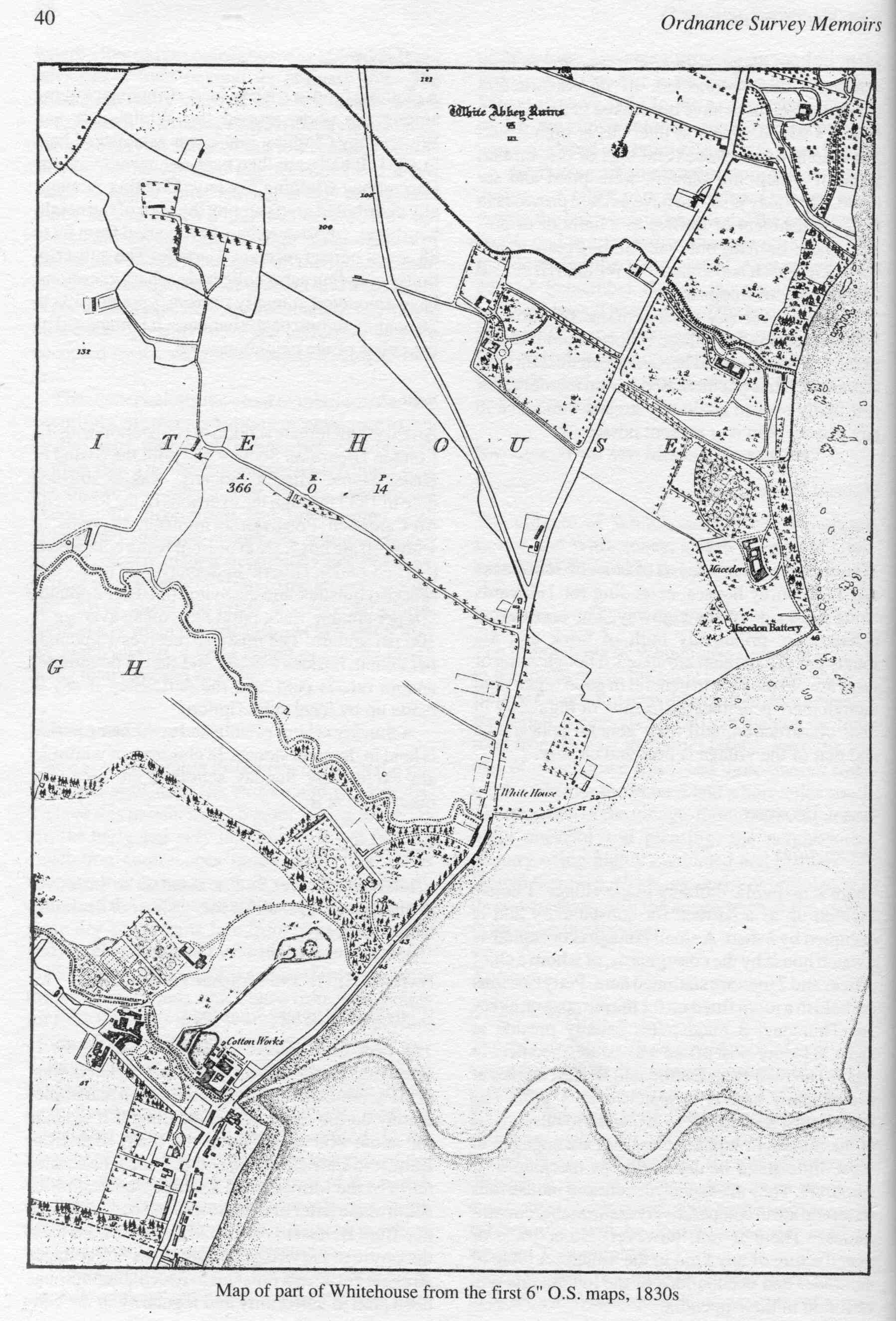

An Ordnance Survey map published in the 1830s (Boyle3, 1839, p. 40) shows several of the features referred to in the above descriptions (see Figure 1, below.) Included are the Grimshaws' cotton twist mill at White House (near the bottom) and the White Abbey Ruins (near the top.)

Figure 1. 1830s Ordnance Survey map3 of the Whitehouse area during the early days of the Industrial Revolution. The cotton twist mill is shown in the lower left corner of the map ("Cotton Works").

| Recent Map of Whitehouse Area |

Figure 2 below shows a current (1988) map4 of the Whitehouse area, with the large arrow indicating Whitehouse. Downtown Belfast is shown at the bottom of the photo. Carrickfergus is located just off the map to the northeast. The small arrow indicates the church and adjoining cemetery where most of the Grimshaws who lived in this area during the early days of the Industrial Revolution are buried (described in a companion webpage.)

Several of the features of the 1830s map (Figure 1, above) can be located on the recent map, including Whitehouse, Macedon, and Whiteabbey.

Figure 2. Recent Ordnance Survey Map5 of Whitehouse area (large arrow), showing location in relation to Belfast.

| Role of Nicholas Grimshaw's Father, Nicholas, in Textile Industry |

Nicholas Grimshaw's father, also named Nicholas, was also actively involved in the textile industry. As early as 1762, the elder Nicholas published an article on bleaching. The text of this article, which was transcribed by Hilary Tulloch, is shown below.

Grimshaw, Nicholas, 1762, Some remarks on bleaching in a letter to a friend. Printed by James Magee.

BPB 1762.5

Transcribed from a photocopy taken from the Linen Hall Library, Belfast,

by Tom W. Grimshaw, 26 May 2000.

The transciption by H. R. Tulloch, 24 Sep 2002, keeps the spelling of the original but substitutes ‘s’ for ‘f’ throughout the text.

SOME

REMARKS

ON

BLEACHING

IN A

LETTER to a FRIEND.

BELFAST

Printed by JAMES MAGEE, M,DCC,LXII

SOME

REMARKS ON BLEACHING, &c

.SIR,

A

s the Right Honourable and Honourable the Trustees of the Linen Manufacture have condescended to receive the Sentiments of the Linen Drapers in respect to any thing, which they think will be conducive to the advantage of the Manufacture; I think it not amiss to offer to your consideration a few Remarks on the Materials used in bleaching: For though the art of bleaching is very common in this country yet the principles, on which it is founded, are very little understood, even by those who practise it. Who then will be surprized that the use of some materials has been prohibited, and some operations condemned as hurtful to the linen, by those, to whom partial representations have been made, and who are themselves intirely unacquainted with the art?Now that I may throw some light on this subject, it is necessary to premise a general account of the several processes and operations commonly made use of to whiten linen.

When linen is sent to be bleached; after being steeped for a day or two in water to soften the dressing used by the weaver, it is very well washed in the wash-mill; then it is boiled in an alcaline lye for some hours: from the furnace it is carried out and spread on the green, where it is allowed to lie for two or three days, the bleachers always watering it carefully when it begins to dry: It is then taken off the green, washed, boiled and spread out as before. These processes the artist repeats till he thinks that the linen is in a proper state for the operation of the Rolling Boards. He then, after washing the linen, soaps it well, and passes it through the boards; it is then boiled and bleached on the green as before. The operation of the boards is repeated oftener or seldomer according to the discretion of the bleacher. When the linen is nearly brought to a sufficient degree of whiteness; in order to give it a brighter colour, it is put into the sour, where it lies one or more days, as the artist judges it to be proper: It is then washed, soaped, passed through the boards, boiled and bleached as before. The souring is repeated once or twice as the linen requires, so as to bring it to a perfectly white colour; when it is blued, dried and finished by beetling.

By this detail it appears that the chief materials used in bleaching are alcaline lyes, sours and soaps.

Now, the better to ascertain the propriety of using these articles in bleaching, it is necessary to observe that the cause of colours in all bodies is by those skilled in philosophy attributed to their oils. Whatever then is fit to penetrate into linen, and, by uniting itself with its colouring oils, makes them miscible with water; so as with ease to be detached from the linen, must be effectual in bleaching; but those, who are acquainted with these matters, assure us that such effects lyes, sours, and soaps are properly adapted to produce.

It is not enough that these materials should be recommended for their efficacy in bleaching, it is also requisite that they should be safe in their use. By this test then let those articles be examined beginning with the Lyes.

It is chiefly of Kelp, Cashub Ashes, Barilla Ashes, a kind called Turkish Ashes, and Pearl Ashes that the bleachers make their lyes. ---- The Kelp is prepared by burning sea weeds by an open fire, till they run together into large hard lumps. The Cashub Ashes have a great resemblance to Kelp; but in this they differ, that in making Cashub Ashes, timber of different sorts is used and not sea weeds. The other kinds of Ashes are made, by burning various kinds of weeds and timber, without causing them to melt.

The chief difference of these ashes consists in their containing a greater or less proportion of pure alcaline salt in a given quantity of ashes. The Pearl ashes are the purest.

In this respect they all nearly agree, that the lyes, of whatever kind of ashes they be made, when fine and of equal strength, have a great resemblance in their properties, that of kelp excepted, which very probably partakes of the nature of sea salt, and is found by experience to bring down the linens more than the rest.

As these lyes are all very hot, there is need of caution in their use; for when they are too strong, the linen is in danger of being tendered by them. Of this the skilful bleacher is well aware, and proportions the degree of their strength, as the season of the year and whiteness of the cloth require; always making the lye weaker, as the weather grows warmer, and the cloth whiter; for which reason no certain standard of their strength can be fixed on.

But there is another thing which would, I am certain, be of singular use in bleaching. What I mean is Lime-water.

I am sensible that the use of Lime in bleaching has been strictly prohibited; and no one need be surprized at this, who knows the manner that lime was used by bleachers, when this law was enacted: they strewed it in substance on the linen, which injudicious method of using it would not fail to make the linen tender, and bring the use of lime into discredit.

It is true that lime is very hot, so are the alcaline ashes, which yet are used with safety; that lime water is also safe is what I now assert; for lime water every one knows may without harm be taken into the human body; which could not be done, were it of so hot a nature as to damage linen. But its safety is not all, I would also recommend it for its great efficacy in bleaching; it is well known that lime greatly encreases the power of alcaline salts, and makes them more readily unite with oils, whence they will be more effectual in whitening linen cloth.

But the best argument for both its safety and efficacy in bleaching is taken from experience. The ingenious Doctor Home, in his essay on bleaching, says that in attempting the discovery of the composition called Muscovy ashes (a kind unknown to us here, though much prized in Scotland) he made a mixture of three parts of lime and one part of alcaline salt, which exactly resembled the Muscovy ashes in appearance and answered all the purposes of them in bleaching, when tried by Mr. Christie a noted bleacher in Scotland.

My own experience is still a farther proof of what I have advanced. I made an experiment some years ago on a few pieces of linen with a lye like that of the soap boilers, but considerably weaker; the trial succeeded to my wish; the cloth was whitened without any damage, and in rather shorter time than by the common method; and I own that only the restraint of the law prevents my continuing the same method yet.

The sours come next under consideration. Those commonly used are either made of bran, buttermilk or oil of vitriol. These all answer the purposes of souring linen, when they are in a proper state for being used. But there is the same caution necessary in the use of them as of the lyes. This the skilful artist knows, and proportions the strength of the acid to the warmth of the weather and whiteness of the linen.

With regard to the choice of the acid, it is proper to observe, that buttermilk and the acid made of bran vary in their degrees of acidity; so that their strength cannot easily be ascertained. Besides, they readily turn into a state of corruption, and then no longer act as a sour, but have all the bad effects of putrefaction. To none of these objections is the acid of vitriol liable. It can be brought to whatever degree of strength the artist chuses; is not affected by the weather, when acting on the cloth; is not liable to putrefaction, and requires a shorter time to effect the purposes expected from its use. These properties I assert from my own experience. I observed indeed, that cloth drawn out of the vitriol sour did not appear so white at its first coming out as cloth drawn out of buttermilk; but when it was about to be put into the second sour, it was rather brighter in its colour.

As Doctor Home has said so much on this head in his essay, I do not think it necessary to insist longer on it.

It now only remains to make some remarks on soap. It is made by boiling up tallow or any other oil with lye (prepared of an alcaline salt and lime) till they be incorporated into one uniform mass, in which neither oiliness nor alcaline acrimony is observable; and which easily dissolves in water.

Now as the sharpness of the salts is sheathed and blunted by the oil, soap cannot be in the least detrimental to linen: yet by the same means it is rendered less active; for which reason it needs the assistance of a mechanical operation. The instrument used for this purpose is the rolling boards.

As a description of their manner of operation cannot convey so compleat an idea of it, as the seeing them at work, it shall not be attempted by me: But so much I will venture to assert, that, when the boards are in proper order for action, and the cloth well soaped and not tendered by some previous process, their action on the linen will be perfectly safe; unless it be kept so long under the boards as to exhaust the soap: which happens, when the operation is very long protracted.

On taking a review of the whole you may observe, that whitening of linen may be effected with perfect safety, if the bleachers be skilful and attentive to their business: but that no process or operation is free from danger, when injudiciously or carelessly managed.

Hence also appears the impropriety of condemning any article used in bleaching: as every article used with judgment is safe; ‘tis only by its abuse that any one is hurtful.

Hence too may be inferred the preference, which ought to be given to the method of bleaching practised here, before that which depends on the application of lyes and sours alone. We have seen that if they be carelessly used, there is danger in their use; more especially when long continued: but it is found by experience, that a much longer time is required for bleaching linen, when the rolling boards are not made use of. Whereas the greatest objection to the boards (even when injudiciously applied) is the making a few holes, which do not by any means cause the cloth to wear the worse: it is tenderness alone, by which its wearing is affected.

I have only to add, that many damages happen to linen, of which the bleacher has no blame. It is well known that many holes are made by the weavers, while the cloth is in the loom, and that there are many parts of their webs so thin and faulty as not to be able to stand bleaching without being holed. Several damages are also made by vermin, stormy weather, and other accidents. Yet all the damages found in the white linen, are laid to the bleachers charge.

What a hardship then will it be on the Drapers, if a law passes prohibiting any linen to be lapped with more than one hole; since it is liable to be holed by so many accidents, which it is impossible for them to entirely guard against or prevent?

It is surely very much to be desired, that there was a free liberty granted by the Legislature to make trials of every thing in bleaching without restraint. While bleachers are confined to tread in the old path, there can be no hope of attaining to that perfection, of which the art is capable. This liberty, I presume, might be granted with safety; for it is every man’s interest to have his linen well and safely bleached, his credit, his profit depends upon it.

Yours, &c.

| Diary of John Cunningham Stewart |

Michael Stewart is in possession of diaries written by his great-grandfather, John Cunningham Stewart, during a visit to Belfast in 1865. He has apparently provided a portion of these diaries to J.R. Colclough who has published them on a website. These diaries provide fascinating detail on the life of the Grimshaws in Ireland in the mid 19th century. The portion of the diaries that are posted on the Colclough website is provided on a companion webpage.

| References |

1Grimshaw, William, 1848, Incidents Recalled: or Sketches from Memory, of the Establishment of the Cotton Manufacture in Ireland; the Irish Volunteers; the Rebellion of 1798; the Irish Parliament; the Union with Great Britain; Emmett’s Insurrection; Distinguished Political and Professional Characters; Remarkable Duels; also, Anecdotes of Fashionable Life; and Robbers Who Infested the Country: Philadelphia, PA, G.B. Zieber and Co., 84 p.

2

Clarke, H.H.S.J., 1938, Thirty Centuries in South-East Antrim, the Parish of Coole or Carnmoney: Belfast, The Quota Press, 318 p.3

Boyle, James, 1839, Parish of Carnmoney, County Antrim - Memoir by James Boyle, 28th April 1839, in Day, Angelique, and Patrick McWilliams, 1990, Ordnance Survey Memoirs of Ireland, Volume Two, Parishes of County Antrim (I) 1838-9, Ballymartin, Ballyrobert, Ballywalter, Carnmoney, Mallusk: Dublin, The Institute of Irish Studies, The Queen's University of Belfast (In association with The Royal Irish Academy), p. 34-105.4

Longfield, Ada, 1821, Notes on the Linen and Cotten Printing Industrues in (Northern) Ireland in the Eighteenth Century: Belfast Natural History & Philosophical Society (reprinted in Proceedings of the Belfast Natural History and Philosophical Society, Second Series, v. 4, Sessions 1950/51 - 1954/55).5Ordnance Survey of Northern Ireland, 1988, Discoverer Series, Sheet 15 (Belfast): Belfast, Dept. of Environment, Ordnance Survey, 1 sheet, 1:50,000 scale.

| Full Text of Ada Longfield Article |

The full text of Longfield's article, referenced above, is provided below.

With the author’s compliments,

AKL.

BELFAST NATURAL HISTORY & PHILOSOPHICAL SOCIETY

1821

SESSIONS SECOND SERIES

1950/51 - 1954/55 Volume 4

[pp.53-68]

Notes on the Linen and Cotton

Printing Industries in

NORTHERN Ireland in theEighteenth Century

by ADA K. LONGFIELD

Reprinted from Proceedings of the

Belfast Natural History and Philosophical Society

418 HAROLD’S CROSS ROAD,

TERENURE,

DUBLIN.

6.3.56

I am informed by Miss Ruth Duffin that you might like to have a copy of the enclosed as part of it deals with the business career of the great Nicholas Grimshaw.

(Mrs.) A.K. Leask.

Notes on the Linen and Cotton Printing Industry

in Northern Ireland in the eighteenth century

By Ada K. Longfield (Mrs. H. G. Leask), M.A., LL.B., M.R.I.A.

Whilst much has been written about the rise and expansion of the linen and cotton industries in the north of Ireland, relatively little attention has been paid to the history of the decoration of the products there by means of printing and stamping. An attempt has already been made by this writer to show that this form of industrial art was not without importance elsewhere in Ireland (especially in and about Dublin and Cork) in the 18th and early 19th centuries, and it is now proposed to deal in detail with such evidence as is available about similar developments in the north, particularly in the neighbourhood of Belfast (Pl. 1 map). If the interest of local readers is sufficiently roused, it is to be hoped that there may be brought to light not only further information but - and this is even more important - a few actual samples of the work.

Though the art of printing and dyeing patterns on woollen and silk materials (i.e. animal fibres) had long been known in Europe, similar efforts on linen (a vegetable fibre) were not nearly so successful. Indeed, for a very long time, black and light brown were the only “fast” shades that could be relied on for direct printing of patterns on linens. Colours had to be added by painting by hand - a laborious and not particularly durable method. It is hardly surprising therefore, that the gaiety of the polychrome floral designs on the cotton “chintzes” that were first imported from the East about the middle of the 17th century, virtually caused a minor revolution in Western fashions for both furniture and clothing. Contrasted with stiff brocades, silks and heavy velvets, the attraction of the light, yet brightly coloured and eminently washable Eastern fabrics was well-nigh irresistible - but their price was high, and hence the efforts of European craftsmen at imitation. Unfortunately for these craftsmen their difficulties were not confined to technical issues alone. In France and England, for instance, and also in Ireland, there was opposition from the other textile trades - even more fearful of the rivalry of home-printed cottons than of imported ones - and it was not till well into the 18th century that objections were officially overcome2. As information on the subject in general is available in various books and articles3, it is unnecessary to add more here. Suffice it to say that by the middle of the 18th century European craftsmen had evolved their own methods for the virtual mass-production of coloured patterns on linens and cottons. If their output did not equal the beauty and individuality achieved by laborious Eastern processes, at least it was relatively cheap and consequently could command a large and growing market.

Thus far, the earliest item found concerning the industry in the north refers, curiously enough, not to the vicinity of Belfast, but to Coleraine. It occurs in the following advertisement in the Belfast News-Letter for March 6th, 1759:-

“These are to give notice, that James Peters of Coleraine, Printer and Dyer, is now begun to print field colours, such as purples and white, reds and white, and black and white, on cotton and linen for women’s gowns; and has lately brought from Dublin some patterns of the best and newest kinds, both of the Drumcondra and other kinds; likewise for handkerchiefs, red and white, claret colour and white, and blue and white. Likewise on fustians, golden olive, green olive, and good black; likewise on woollen goods, scarlet in grain, cherry colour ditto, pink ditto, purple in grain, golden olive, claret colour, snuff colour, London browns, black, blue, green, French yellow and common ditto. All these he does to as good perfection as any in this Kingdom, and a great variety of other things, too tedious here to mention; and will, if demanded, find security for any of the above performances. Dealers or those who have large parcels to do, may meet with proper encouragement. He will give all reasonable encouragement to any who are pleased to favour him with their commands. Dated at Coleraine, this 1st of March, 1759. N.B. As the proper season for laying down field colours is now come, persons who intend having any cotton or linen printed this season would do well to send them as soon as convenient. And as my work is spread through the counties of Antrim and Derry, I appeal to its proprietors for a character”.

1. MAP of Belfast and environs showing approximate location of textile printing works, c. 1759-1800. (Adapted from Benn’s History of Belfast” 1823, by H.G. Leask.)

A few words of explanation will serve to indicate the significant features of this advertisement. For instance, the patterns from Dublin may have included wood-blocks (the “other kinds”) as well as the newer metal plate types which were a special feature of the Drumcondra factory. Indeed in 17524 the proprietors there claimed to be the inventors of the idea, and though this has not been absolutely authenticated, Drumcondra was undoubtedly amongst the earliest centres in Europe to use metal plates. Furthermore, later evidence5 shows that the proprietors - Theophilus Thompson and Francis Nixon - were induced to take their methods “to another Kingdom” (i.e. England), and as they were in the process of selling up in 17576, it would have been easy for Peters to acquire some of their stock. Anyway the notice indicates that Peters proposed to follow the newer method, just as other advertisements show that it had been adopted at the Templeogue and Leixlip factories in 17587.

The great advantage of metal plates - as compared with wood-blocks - was that designs could be larger, and the reproduction of lines and details sharper and finer, and this helped more ambitious kinds of patterns suitable for furnishing purposes. But at first it was possible to print in only one colour from them, and polychrome effects had still to be done by a series of wood-blocks or by hand painting or “pencilling”. Hence the choice of single colours and whites that Peters gives; hence, too, his anxiety to get his orders in soon as May to September was the “proper season” for carrying out the many processes that were essential in those days before the rapid bleaching qualities of chlorine8, and the use of other chemicals had been discovered. Thus, to achieve decoration in red (one of the popular colours for this work) for which no direct printing method was then known - adequate outdoor space was very necessary. After the fabric had been treated with suitable mordants (fixitives) it had to be dried for twelve hours, rinsed in running water, rolled into bundles for pressing the water out, placed in a bath of madder or cochineal, bleached on the grass for five or six days (the early morning dews of May to September being considered particularly effective) and watered several times a day lest it become too dry and the colours be dulled. All this, of course, was in addition to the actual printing process, whether it was the background9 or the pattern that was to appear in red. Finally there are the explicit references to “dealers” and to “persons who intend having any cotton or linen printed this season” indicating that Peters undertook the retail decoration of goods brought to him for that purpose, whereas later on this “piece” system became far less common - printers finding it more lucrative to make, or anyway to choose, their own materials in bulk.

Another provincial enterprise of a less ambitious nature, but also known from advertisements, was scheduled to start operations in the Spring of 1771:-

“Newtownards. This is to give notice, that on the 7th of May next, Hugh McCutcheon intends to commence the stamping Business in this Town, next Door to the new Brewery, where he will stamp dark and China Blues of a good standing Colour. As he has a choice Assortment of good China Blue stamps for Gowns and Handkerchiefs, either in Linen or Cotton, such as incline to favour him with their Commands, may depend on having Work done with Care and Punctuality. Dated Ap. 25th, 1771.”10

Although this notice is not so informative as that of Peters, it is fairly clear that McCutcheon only proposed to establish a relatively small plant. By confining his activities to monochrome patterns that could be achieved with metal plates alone, and to productions in one colour alone (blue) initial expenses for equipment could have been kept down to the minimum. “China Blue” was, moreover, a shade that had been made particularly popular by imported “Canton” china, and as the technique for good results through the use of indigo, wax and tallow was not quite so lengthy or so complicated as for productions in red, printing in blue was the obvious choice for many minor establishments.

Apart from the above notices, nothing further has so far been found out about Peters or about McCutcheon. Possibly their ventures were so successful that they did not need to advertise again. Unfortunately, though, it is just as likely that they belonged to the short-lived efforts of two to four years duration or so for which the industry - not only in Ireland, but also in England and France - was unhappily notorious. Costs of initial outlay, long credits to drapers, etc., etc., involved a more continuous command of adequate capital than many who optimistically entered the business seem to have been prepared for11.

Nicholas Grimshaw is the first as well as the most famous name connected with linen and cotton printing near Belfast, and the rapid expansion of the industry there between 1780-1805, was largely due to his example. By the time he settled near Belfast he was profitting from previous not altogether happy experiences in the trade, for his father - also called Nicholas - went bankrupt in Manchester in 177112, whilst he himself must have been left without employment when (owing to differences with the owners) he abandoned his position as manager at the linen and cotton printing factory on the Isle of Man early in 177613. Thence, however, he moved to Greencastle. Fortunately a fairly coherent picture of the development of his successful career in Ireland can be obtained from the remarkable series of advertisements that appeared at intervals from 1776 till his death in 1805.

Grimshaw’s first announcement on the 2nd of August, 1776, not only clearly defines the initial scope of his operations (monochrome patterns from metal plates and polychrome “chintz” from wood blocks, etc.) but also includes details of the strenuous method by which he proposed to establish a widespread clientele:-

“Linnen, Cotton and Calico Printing. Nicholas Grimshaw, from England, takes this Method of acquainting the Publick that he has begun to carry on the Printing Business in all its various branches, from one Colour to full Chintz, at Green-Castle, within three miles of Belfast, where Merchants, Shop keepers, and others, may have Handkerchiefs, Garments, Furniture, etc., printed to the greatest Perfection, and upon reasonable Terms; and for the Convenience of such as please to favour him with their Commands, he purposes being at the following Market Towns on the under-mentioned Days, where a great Variety of Patterns may be seen, viz.

At the shop of Mr. Wm. Hillditch, Belfast, every Friday.

Mr. John Bowman’s in Carrickfergus, on Saturday the 10th August.

The shop of Mr. William Hillditch, Belfast, on Monday 12th August.

Mr. John French’s, Randalstown, on Wednesday 14th August.

Mrs. Huey’s, Maghrafelt, on Thursday the 15th August.

Mr. Charles Hyndman’s, Ballymena, on Saturday 17th August.

Mr. Wallis’s, Banbridge, Monday 19th August.

Mr. Leatham’s, Hillsborough, same Afternoon.

Mr. John Hastings, Lisburn, Tuesday 20th Aug.

Mr. Geo. Park’s, Armagh, on Tuesday 27th Aug.

Mr. John Murphy’s in Rathfriland, Wednesday 28th August.

Mr. Geo. Black’s in Newry, on Thursday 29th Aug.

Mr. John Shaw’s in Lurgan, on Friday 30th Aug.

N.B. Linnens, Cottons, &c. are took in to print at the above Places, either brown or white, and delivered there when done.”14

It is interesting to note in the above the number of localities from which Grimshaw thought “piece” orders for his printing might be drawn. Still more interesting is his notice a year later (1777) because it shows that by then he no longer considered it necessary to travel round in person. Those who wished to see his new patterns were invited to view the collection in Belfast.

“Nicholas Grimshaw, Linnen, Cotton, and Calico Printer, at Greencastle, near Belfast, has just received from England, a choice Assortment of New Patterns for Gowns, Furniture, Handkerchiefs and Waistcoats; and has begun Work for the Summer Season. A Book of his Patterns, with the Prices annexed, is left at Mr. Atkinson’s, Teacher of Mathematics, opposite the New Sugar House in Waring Street, Belfast; at which Place Attendance will be given by the Undertakers on Fridays from 10 o’clock till 2, to receive Orders, and on other Days, Mrs. Atkinson will shew the Patterns, receive Goods, and deliver them to the Owners when finished. This opportunity is taken to remark, that as this Business can only be carried on to best Advantage from the Spring Season till the Latter End of Autumn, the said Grimshaw is determined for the future not to take in Goods later than the Middle of October. N.B. Cloth full white will be most acceptable, as the Work will admit of being better done, and more to the Satisfaction and Advantage of the Owners.”15

A short announcement in 1778 is useful mainly as supplying a description of the colours of his (then) new patterns. As these included “Blue, Green and Yellow Grounds” it shows that he did true “field” shades (i.e. single coloured backgrounds with the design in white) as well as the usual styles on a white ground “Purples, Reds and elegant Chintz for Gowns and Furniture.”16 Further re-adjustments in organisation are indicated, however, in notices in 1779 and 1780. Apparently it was again found advisable to provide facilities for viewing each new season’s patterns in the country, and not only in Belfast:-

“Linen and Cotton Printing. Nicholas Grimshaw having lately completed his new Pattern-Books, they who live at a Distance and have Cloth to print, may by writing to him, or Mr. William Beggs, next door to the Old Sugar House, Belfast, be accommodated with a Book of said Patterns, returning it after having made their choice. His Patterns may likewise be seen at Mr. Leatham’s, Hillsborough; Mr. Thomas Forcade’s, Lisburn; Mr. Thomas Herdman’s, Ballymena; Mr. Samuel Morrow, Larne; Mr. John Bowman’s, Carrickfergus and at his Warehouse, Belfast; where Cloth will be received for printing, and delivered to the Owners when finished, Carriage free. N.B. Nicholas Grimshaw has just finished some Cottons and Linens, which he will sell Wholesale, at his usual Low Prices. Greencastle, near Belfast, 26th May, 1779.”17

Though Grimshaw obviously still desired to keep up his orders for retail decoration, the last sentence in this quotation reveals the beginning of a change over to the less troublesome system of wholesale dealing only. Again, in his notice in 1780, people are invited to view his new patterns at the printfield itself, but the local agencies are reduced to three in number - at Lisburn, Larne and Ballymena - whilst his selection of ready printed wholesale goods is more clearly defined “Chintz, Cambricks, Handkerchiefs, Waistcoats and Cottons.”18 As the reputation for the high standard of his printed work became more firmly and widely established, and his sales of his own productions increased, it gradually became possible to abandon the “piece” trade altogether. Evidence of the completion of this change, and of the fact that within ten years he was sufficiently successful - in conjunction with another eminent merchant - also to manufacture the actual material for printing on, appears from the following entry in 1785:-

“Printed Cottons and Callicoes. Nathaniel Wilson and Nicholas Grimshaw have for Sale, at the former’s Ware-house, in Waring-street, Belfast, an extensive Assortment of printed Cottons and Callicoes, which they will sell (by wholesale only) on very cheap terms, for ready money, or bills on Dublin and Belfast. As these goods are both manufactured and printed by themselves, they are enabled to sell on the lowest terms . . . much cheaper than such Goods have hitherto been sold in this Country. Belfast, 25th November, 1785.”19

Delivering finished goods to Wilson’s town warehouse was a very different proposition from peddling his own books of patterns, or dealing with “piece” orders collected through Mrs. Atkinson or Mr. William Beggs! Grimshaw had indeed succeeded, and if he was lucky in having got established just before a short period of comparative prosperity for this industry in Ireland20, his ability to weather various commercial storms which lay ahead, indicates on what sound foundations his business reputation was based. Meanwhile, however, a steady rate of progress was maintained and for a time there seem to have been two printfields in operation. Thus the notice in the summer of 1788 refers to the constant supply of new goods “every week arriving from their Printfields”21 whilst earlier in the same year an insertion about thefts incidentally shows that the second green was located at Whitehouse. Unfortunately, thefts from bleaching and printing greens were then only too common almost everywhere in Europe22, but the following is interesting because it describes the patterns:-

“Stolen. Off the Bleach-Green of WILSON and GRIMSHAW, near Whitehouse, on Sunday Night last, three Pieces of printed CALLICO, 28 yards long each. The Patterns - running Sprigs, printed with black, purple, two reds and yellow; the ground is of a yellowish cast, and there are yet wanting to compleat the pattern the two colours of blue and green23. It is therefore hoped that no person will purchase Goods in such an unfinished state, but rather stop them if offered for sale, and secure the Person offering them. …”24 (Reward of £50 for conviction, etc.)

After Wilson’s death later in 1788, Messrs. Haslett, Strong and Co. became Grimshaw’s principal agents in Belfast. The entry in 1789 about his “Printed Cottons, Calicoes and Muslins … Chintz Furniture, Copper-plate ditto; Shawls and Handkerchiefs”25 being on sale with Haslett, Strong and Co., is corroborated by that firm’s own statement that

“they are now largely supplied (from the Printfield of Mr. Nicholas Grimshaw) with dark chintz Callicoes, of the newest and most fashionable patterns, for the Winter Season.”26

Furthermore there are references to daily deliveries in the spring of 1792; to twice weekly ones in that autumn27, and to the expected supply of the new season’s patterns (each Tuesday and Friday) in the spring of 179328. But shortly after this last notice appeared the partnership of Haslett, Strong and Co. was dissolved and the “Sale of Mr. Grimshaw’s printed Goods” was transferred to Messrs. Brown, Gaw and Co.”29, and it is in their advertisements that deliveries are then notified to the public30.

In addition to these special agents, other dealers naturally stocked his materials too. In 1796 Hannah Kirbee, of High Street, Belfast, expressly refers to her

“neat Assortment of Mr. Grimshaw’s New Printed Mourning and Fancy Callicoes”31

and probably most drapers in the north kept “Assortments” for sale. That the demand for his goods was by no means purely local is shown by a Dublin firm’s insertion in a Cork newspaper of 1793:-

“Francis and William Kirkpatrick, No. 24 Merchant’s Quay, Dublin … now largely supplied with Callicoes Printed by Mr. Grimshaw of Belfast, which are acknowledged to be the best ever executed in this Kingdom, and equal to any imported from England.”32

Although “the best in the Kingdom” was rather a common phrase in advertisements of the period, nevertheless the specific use of Grimshaw’s name reflects the esteem attached to the quality of his printed work.

Information about Grimshaw is to be found in other sources

too. Thus the Proceedings of the Dublin Society33 contain corroboratory

evidence about the high standard of his manufactures. In 1784 (the last year

in which these particular awards were made) Grimshaw and Wilson obtained the

first premium “for best printing Work of five Pieces of Cottons not less

than 28 Yards34 each, nor less than 45 Irish Beers, and 31½ inches broad,

printed with dark or coloured grounds” in addition to the first premium

(also £20) for manufacturing the “best five pieces of Callicoe” etc. But

if advertisements in general indicate considerable prosperity up to about

1791, several passages in the Drennan Letters35 illustrate the

difficulties which at intervals beset some of the larger cotton manufacturers

and printers during the last decade of the century. According to this

correspondence Grimshaw was seriously affected by the financial crisis of

179336. Fortunately he managed to carry on, though many other merchants failed

completely - amongst them one of his most serious rivals for the local trade,

the Balbriggan-Dublin firm of O’Brien, Comerford and Clarke. For the “accommodation

of North Country Dealers” this firm had opened a warehouse in the High

Street, Belfast, in 178837. It was under the direction of Mr. William Martin,

and for a few years supplies of plain goods from the factory at Balbriggan,

and of printed stuffs from the printfield at Palmerston (near Chapelizod) were

offered there at “Dublin prices”.35 Incidentally this special facility for

purchasing these productions perhaps explains why the only known

example of 18th century Irish printed linen and cotton that survives in

Belfast (in the Municipal Museum and Art Gallery) is a piece of Clarke’s

well authenticated “Volunteer Furniture” pattern39. How spectacular was

the firm’s collapse in the summer of 1793, may be judged from Drennan’s

letter from Dublin to his brother-in-law in the north, “Comerford and O’Brien

failed for exactly £67,000, and might have done so for £200,000 as their

credit was great the day before …. Last year, at this time, their goods were

carried away as fast as they could load them, and now, for some time, not a blade

[bale]

is sold.”40

From the same source it appears that Grimshaw was again in difficulties in 179941. Yet once more he succeeded in carrying on, and in 1800 still ranked as one of the most prominent men in the “cotton branch” for when the Irish House of Commons resolved into Committee on “his Majesty’s message relative to the Union” he was called on to give evidence not only on behalf of all the Irish cotton manufacturers and printers, but especially for those in and near Belfast42. According to this evidence he considered that the commercial propositions of the Union (as they then stood) would prove fatal to “that great and rising manufacture”. The protecting duty of 30 per cent. together with charges, etc., of 10 per cent. was not sufficient to preclude the Irish market from injurious competition, so that lowering the duties would give to English cotton a fatal advantage over the Irish. Furthermore he estimated that a capital of not less than £192,000 had been invested in the trade in the vicinity of Belfast alone, and that this gave employment to “an immense number of persons” - employment which might irretrievably be lost. Nor was he content with this statement alone. Some ten days later a petition43 was presented from “Nicholas, Thomas and James Grimshaw, of Whitehouse, Cotton Manufacturers, and their Printers, Spinners and other People employed about their Manufacture”. In this, whilst expressing great loyalty to the Royal Family, the petitioners also emphasised their grave concern over the proposed Union - a measure rejected by the “uninfluenced sense of the House last Session” but now being brought forward again. The constitution of 1782 had enabled their trade to flourish, especially in Belfast; they dreaded the proposed change, etc., etc.

In actual fact, the cotton industry in Ireland continued to enjoy protective duties for some twenty years or so after the Union, and printers of cotton goods benefitted accordingly. At this distance of time, however, perhaps one of the most interesting items in Grimshaw’s petition is the reference to his sons, Thomas and James. As this remarkable man (his portrait is shown in Pl. II) had fifteen sons and four daughters, it was natural that the business should have gradually become a family concern and Directories indicate that from 1800-03 the Dublin warehouse at 18 Merchant’s Quay was held in the names of “Nicholas, William and Thomas Grimshaw and Co.”. Later the “Printed Goods of Whitehouse manufacture” were sold through the firm of Peck and Grimshaw, at 14 Ussher’s Quay44 whilst Thomas O’Neill and Co. seem to have handled most of the Belfast sales for “Messrs. Thomas and Edmund Grimshaw.”45 Nicholas himself did not live long into the new century and his death on Sunday the 28th of April, 1805, at the age of 56 - from a tedious disorder, bravely borne - is duly reported in the Belfast News-Letter of the 30th April. He was buried at Carnmoney, in the graveyard of the parish church, and thus within a few miles of Whitehouse, the “neat village” which owed so much to his enterprise.

His career has been related in considerable detail, not only because of its intrinsic interest, but also because his commercial achievements place him amongst the greater personalities of the period in this industry, e.g. the Peels at Bury, in Lancashire, or Kilburn at Wallington, in Surrey. Moreover the business continued in family hands long after his death. Of the sons actively concerned, three - Thomas, Edmund and James - were still listed as calico printers at Whitehouse in Bradshaw’s Directory of 1819, and Grimshaws are also referred to in the description of the cotton manufacturing and printing works there when Lewis’s Topographical Dictionary of Ireland was produced in 1837. Although printing on cotton has ceased to be done at Whitehouse for many years, descendants of the original Nicholas have always been engaged in various branches of the textile trade in the north of Ireland.

2. PORTRAIT of Nicholas Grimshaw. (Original painting in the possession of C. E. Duffin, Esq.)

Barely nine months after Grimshaw settled at Greencastle, at least one other English printer who came to the north, also employed the method of working through local agencies to collect orders for retail decoration on linen and cotton, and useful information about the early years of Richard Williamson’s venture - first at Gilford and a little later at Annsborough - is provided by several lengthy advertisements. For instance, in May, 1777, a preliminary announcement states that

“Richard Williamson, lately come to Ireland …. intends to begin the Business of printing Cottons, Linens, etc., upon the Ban-Water, near Gilford; for which purpose he is now getting ready a neat Assortment of the newest Patterns from Dublin… N.B. The names of the Towns where the Patterns will be placed, and the Persons who shew them and who take in the Cloth, will be inserted in an Advertisement, when they are ready for publick View, which will be in about three Weeks.”46

Two months later the detailed insertion that “he has now begun the Business …. at Tullilish, near Gilford” does appear, and those who send him cloth to print are assured of good and speedy execution.

“The Patterns are to be seen at Stewart Hadskis, Belfast; John and Samuel Hill, Lisburn; Charles Gorman, Banbridge; Rachael Malcolmson, Lurgan; Henry Walker, Portadown; Thomas Pepper, Rich-hill; --- Ankettle, Bookseller, Armagh; William Crozier, Tanderagee; Thomas Greer, Dungannon; and Samuel Craig, Tullilish, and Cloth taken in to print. N.B. Proper Discount will be given to Shopkeepers.”47

In March, 1780, the advertisement is dated from Annsborough, suggesting that he must have moved his “Printfield” there. It gives a still longer list of places at which his new patterns “procured at Great Expence” could be seen - with the exception of Belfast, Lisburn and Tullilish, all those mentioned in 1777 are repeated, whilst new centres include Newry, Four Mile House, Dromore, Hillsborough, Antrim, Markethill and Moy48.

Yet another notice (also from Annsborough) in 1781, reminds prospective customers that “business for the season has begun” and gives a slightly less ambitious lists of agencies. Banbridge, Lurgan, Portadown, Richhill, Armagh, Tanderagee, Dungannon, Newry, Four Mile House and Dromore are still included, but Hillsborough, Antrim, Markethill and Moy (all on the 1780 list) are omitted, and only two new centres are added - Loughgall and Glenavy49. Some of these changes were doubtless made not only to avoid competition with Grimshaw, but also to facilitate customers in more remote areas. The agency in Belfast, for instance, does not appear again after 1777, whilst the opening of one in Loughgall presumably represents an attempt to extend the trade acquired in Armagh. Despite all these efforts, however, Williamson does not seem to have been particularly successful, and the project must have closed down some time prior to 1791 since an advertisement about letting the “Annsborough Farm and Bleach-Green” refers to “offices for cutting, dressing and dying corduroys and callico printing where these businesses have been carried on for some years past.”50 The most interesting feature of all this, of course, is not the failure to achieve success on Grimshaw’s scale, but the evidence it affords of a demand for retail printed decoration (even in relatively small centres) sufficient to support such a business for at least several years.

If Nicholas Grimshaw was the “Father” of the printing side of the industry in Belfast, some of his early success was due to his connexions with Robert Joy, the “Father” of cotton manufacturing itself there, and one of the founders of a firm which later did printing too. The story of how Robert Joy (inspired by what he had seen in England in 1777) and Thomas McCabe first introduced the spinning of cotton yarn at the Belfast poor-house has been recounted in detail by Edmund Wakefield51, and need not be repeated here. It should be noted that the project got little encouragement at first, except from Grimshaw, who helped in making some of the early spinning and carding machinery for them. Later (about 1781) Joy and McCabe abandoned their original idea of a poor-house industry - save for employing some of the children - took McCracken into partnership, obtained superior machinery and set up their own independent cotton manufacture. Indeed by 1784 the art may be said to have become firmly established in Belfast for others as well as Grimshaw and Wilson followed their example, and for several years most of the Dublin Society premiums for making various types of cotton cloths went to northern firms52.

Exactly how soon Francis Joy53 started to develop the printing side is not absolutely clear, though it was certainly not later than 1787. Thus, whilst an advertisement in 1785 refers to stocks of printed goods received from “Print Greens in the Vicinity of Dublin and Belfast”54 the following insertion indicates that his own premises for printing were definitely at work, at the Falls, in the autumn of 1787:-

“Stolen. Off the Printfield of Francis Joy and Co., at the Falls, a Piece of Printed Callico, about 30 yeards - broad striped Pattern, Colours - black, chocolate, two reds and lilac. It had been dyed the day before it was stolen, and from its unfinished state, particularly in the white, was unfit for sale. Shopkeepers, Bleachers and others, are requested to stop it if such a Piece of Goods is offered to them ….”55

(Reward offered, etc.). Incidentally there are further insertions about this theft and another one in Jan., 1788, and it was surmised that the pieces had been taken by “some of the Canters who sell goods thro’ the country.”56 Evidence of a more general nature also occurs in ordinary notices for 1788 and 1789:-

“Old Cotton Manufactory. Francis Joy etc., and Co., having at great Expense procured some of the best workmen in the different Branches of the Cotton Manufacture and Printing, are daily receiving from their Printfields at the Falls, a Variety of Garment and Furniture Calicoes and Cottons, Shawls, Handkerchiefs, etc., etc., which will in future be disposed of at the Warehouse of Forsyth, Shaw and Co., Rosemary-Lane …. no expence spared … goodness of the colours and execution of the work …. The greatest encouragement will be given to those who buy with Cash or Bills at Short Sight ….”57

As other somewhat similar entries under the full heading “Joy, Holmes and McCracken” appear at intervals from 1791 till early in 1795, the company certainly continued to be active throughout those years58.

The end came, however, in the summer of 1795, when the partnership was dissolved by mutual consent59 and some of the equipment was advertised for sale. This included “some Printer’s Blocks, cut with new and fashionable Patterns, several of them never in use, and most of them little worn; some seasoned Sycamore and Holly ….”60 Apart from the above, a few spinning jennies, etc., little else was listed for disposal, and it is probable that McCracken took over the greater part of the printing machinery in order to start independently at Knockairn. In any case the following notice appears in 1796:-

“New Printed Callicoes. Henry Joy McCracken. Late of the House of Joy, Holmes and McCracken, having lately commenced the Printing Business on his own account …. has made an Agreement with Mathew Smith, No. 24 Bridge-Street, for the sale of his Goods; they will be delivered there ready for Inspection twice a Week, from his Printfield at Knockairn ….”61 Smith’s advertisement is also given in the same issue and besides explicitly mentioning printed calicoes from McCracken’s field, he adds that they will be sold cheaply for “Good Bills at 61 days, or 4d. per Pound Discount for Money.”62

Whether McCracken was really very successful is doubtful. Certainly by 1816, when W.S. Mason’s Statistical Account of Ireland was published, the “manufactory for stamping cotton on a small scale, at Knockairn” was then described as being in the hands of a Mr. Joseph Ashcroft63. But the fact that “printed callicoes” alone are referred to in the advertisements suggests (if the term was being used correctly) that he worked on imported material only, “calico” at that time being conventionally applied to cotton cloth made abroad, as distinct from that manufactured at home. Hence the numerous references to printed cottons as well as to printed calicoes.

It is possible that the closing down of Joy and Co. and the subsequent dispersal of staff indirectly led to the setting up of works at Muckamore and at Milltown, Falls, for both Abel Brown and William Farquhar claimed to have been previously engaged in the trade. So far little has been found about them, but according to a notice in 1795, the former manufactured his material too:-

“Abel Brown (now living in Muckamore) begs leave to inform …. (that having lived for many years with a late eminent house in the Cotton-Printing business) has now commenced the Cotton Manufactory and Printing Business on his own account …. George Hadskis of Smithfield, Belfast, will in future sell his goods in the above line….”64

Farquhar’s announcement in 1796, though less ambitious is more interesting, because it suggests that there was still a demand for the older “piece” system:-

“Cotton Printing executed by William Farquhar, Milltown, Falls. Where Wholesale Shop-Keepers and others who choose to Print their own Callicoes, will find Variety of Patterns suitable to the season, and adapted to the different Quality of Goods. Being regularly bred to the Business, he hopes to Finish his Work in a Manner to please, and on such Terms as will be Productive of advantage to those who employ him.”65

Nor was it only those “bred to the business” or already engaged in manufacturing plain cotton goods, who seemed to find an attraction in starting their own printing fields. Thus a whole series of notices provides information about George McCamon - a linen draper and haberdasher who abandoned an apparently flourishing concern in favour of textile printing. Presumably it was dealing in printed fabrics that inspired the desire to produce them himself and it is interesting to find that in 1791 his stock included “French and Versailles Chintz Calicoes” (i.e. “Toiles de Jouy” so rarely listed in Irish advertisements) as well as the usual assortment of English and Irish printed materials66. His decision to “enter into another line” must have been taken early in 1792, for by that autumn he was selling off the remainder of his drapery and haberdashery goods and endeavouring to collect outstanding accounts67, whilst the following insertion shows the new business actually in operation by January, 1793:-

“New Wholesale Cotton Warehouse. George McCamon and Co. have just received from their Printfield at Strand-mills, a variety of Printed Callicoes and Cottons. The Patterns are new, fashionable, and suitable to the season. These goods being manufactured and printed under their own inspection, they are enabled and determined to dispose of them on such Terms as will be found agreeable to their Friends and the Public.”68

Later the same spring69 a cheerful note of expansion is suggested by notices about the removal of the warehouse from High Street to Arthur Street “for greater convenience” and by the addition of Velveteens, velverets, Thicksets and Corduroys”70 as also of cotton wrappers and printed linens to the list of goods produced. But in 1796 it was announced that the printed goods would be sold through Mr. Isaac Patton, and that the house in Arthur Street would be disposed of 71. McCamon then seems to have moved to Malone as it is from there that his advertisements are dated in 179772.

It so happens that one of Patton’s own notices in July, 1796, not only expressly mentions the weekly deliveries from McCamon, but also includes similar deliveries (“Calicoes of the Newest Patterns”) from Dalrymple, Graham and Co. of Carnmoney73 - thus incidentally supplying what appears to be the first reference to the latter printfield, where work presumably started either early in 1796, or late in 1795. In any case “William Graham and Co.” acquired a shop in the High Street “nearly opposite to the Donegall arms” in 1798, and according to their advertisements the variety of the patterns from Carnmoney met with “much approbation.”74 In 1799 a notice shows that David Bigger and Mark Patton were the other partners in the “House of William Graham and Co.” and that “for the more completely carrying on the same Business” they were taking Mr. Aaron Stanton into partnership75. The firm was to be known as Graham Stanton and Co., and the printed goods were to be sold at Mark Patton’s warehouse in the High Street. Yet another change is indicated by insertions in 1803 and 1805 when the “new and fashionable Patterns” from the printfield of “Messrs. Aaron Stanton and Co.” were being disposed of on commission to wholesale dealers like James McGowan and Isaac Patton76. But it is worth noting that the firm is still listed (under the last mentioned title) in Bradshaw’s Directory of 1819, and this pleasant example of continuity of proprietorship probably owed much to the financial resources of the partners originally concerned.

Before turning to some of the more general issues involved, brief references must be made to two other printing establishments - Patrick Gaw and Co. at Stonyford, and William Hall and Co., at Woodburn, Carrickfergus. Relatively little is known about either, but judging from advertisements in 1787 and 1788, for at least a time Patrick Gaw’s cotton manufacturing and printing business may almost have rivalled that of Joy’s in importance. For instance, the “daily deliveries” from the “Printfield at Stonyford” to Henry Haslett’s warehouse in Rosemary Lane included “Cotton and Linen Handkerchiefs, Cotton and Calico Shawls, Furniture and Garment Cottons and Calicoes” in fact nearly everything that could be embellished by means of printed decoration77. As work at William Hall’s printfield at Woodburn apparently did not begin till 180478, and the whole concern (including a “copper-plate Press, with a variety of Plates, nearly new, a Callender”79, etc.) was put up to auction in March, 180580, the enterprise lies outside the limits of the period specially dealt with here. It is mentioned, however, because later proprietors were more successful. Thus Dunn, Stewart appear as calico printers at Woodburn, in Bradshaw’s Directory of 1819, and also in Pigot’s Directory of 1824.

CONCLUSION

It has been remarked that research is useful only when related to the integrated totality of knowledge. In the foregoing pages an attempt has been made to link the history of the northern linen and cotton printers with that of their contemporaries elsewhere. Doubtless many more details could be added (especially by those with local knowledge) but this writer feels that enough have already been included to show that decoration by means of printing played a fairly important - if hitherto rather neglected - part in the 18th century textile trade developments of northern Ireland. Above all it is hoped that the discovery of some authentic specimens, or of an actual “Book of Patterns” may yet enrich the sum total of information about this form of industrial art at a period when it was really still in the nature of an art, and before the mechanical perfections of 19th century machinery had virtually eliminated the earlier attributes of a craft. To cover the whole subject at all adequately would take more space than is permissible, or indeed desirable, here. Consequently it must suffice merely to touch on certain features, and to remind readers that much can be learnt from the books and articles listed in the footnotes. For instance, it has not been possible to trace many of the later 18th century changes in techniques of bleaches and dyes. Yet it is fairly obvious that Grimshaw, Joy, etc., must have availed themselves of current chemical discoveries as quickly as did their English and European contemporaries. Similarly, none of the later advertisements explicitly refer to the use of metal plate cylinders (instead of metal plates) yet the “daily” and even “twice weekly” deliveries could hardly have been maintained without such aids to rapid mass production. As copper-plate cylinders are definitely stated to have been employed in Dublin - notably by Edward Clarke at Palmerston - soon after the invention of the process by Thomas Bell, about 178481, they were surely adopted in the north at much the same time.

The work involved in transferring patterns to blocks, metal plates, or to metal cylinders, and the discovery of a way whereby the time factor for the last named could be reduced from six months to six days, leads on to a consideration of the basic problem of pattern designing. The imperative need for a continuous supply of fresh designs is obvious from the frequent notices about “this Season’s Patterns” or “the newest Spring and Summer Patterns”, etc., etc., and these would have included not only smaller types suitable for clothing, but also larger pictorial and semi-pictorial compositions adaptable to hangings, wall and furniture coverings, and to decorative and commemorative handkerchiefs. Many of the earlier advertisements refer to “new Patterns” obtained either from Dublin or London, though some must also have been executed locally. Unfortunately, apart from documentary evidence about constant changes, little is really known about the actual artistic merits. Until some fully authenticated examples are found it can only be supposed that the patterns often resembled those seen in the rare pieces of undoubted 18th century English and Irish work that are preserved in various collections, e.g. in the Victoria and Albert Museum, London, or in the National Museum, Dublin. Conscious as well as unconscious “borrowing” and copying of particularly popular patterns was not at all uncommon, and indeed it was the growing excess of cheap provincial imitations (especially round Manchester) that led to the passing of the first English copyright acts protecting designs for printing on cotton, linen and muslin, for the amazingly short periods of two, and then three months, in 1787 and 1794, respectively82. Yet even these much copied London patterns were often based on models originating in France. There the value of art in industry was so well appreciated that eminent painters like J.B. Huet, Pillement, Lebas, Vernet, etc., were employed at the great textile printing centres such as Jouy (near Versailles), Beautiran, Nantes, Rouen, etc., and the international reputation of the famous “Toiles” owed much to this practice. It is worth remembering, though, that from about 1745-90, the Dublin Society83 endeavoured to raise the standard of Irish designs by offering premiums for patterns suitable to linen and cotton printing, and to certain other manufactures too (wall-papers, delft, carpets, etc.).

If specimens are needed to demonstrate merits so loudly acclaimed in advertisements, business ledgers are also needed to supply details about output, consumption, etc. So far there is no means of assessing what the printing activities of the various firms noted here actually amounted to - even for any one year - and data from account books, etc., especially of the larger firms, might be very illuminating. The survival of a few such books is, incidentally, just as likely as that of some pieces of printed material with marks on a turned in edge, maker’s names being usually placed at the end of each roll of cloth. Undoubtedly the general evidence from advertisements, etc., suggests that decoration by means of printing was really important in helping to increase the demand for linen and cotton goods, and so much have benefitted those manufactures very considerably. Increased trading facilities through the opening up of outside markets (e.g. especially North America81) after 1779, and the Linen Board’s bounty system on the exports of printed as well as of plain linens (1780) readily explains the spate of development between 1779 and the outbreak of the French revolutionary wars. Prior to 1779, however, export to England or the colonies was not allowed, so that until then demand must have been purely local, and it is the apparent extent of this local demand which is so interesting. Apart from any other reasons - less taxation, etc., etc. - the business outlook must have been fairly encouraging when it attracted Grimshaw to come over in 1776, and Williamson in 1777.

Finally it may be noted that the very nature of the work involved in printing on linen, cotton or muslin necessitated - even in the earlier stages of technical developments - a great deal of direct supervision. The proper use of blocks, plates, cylinders, colours, mordants, dyes, etc., etc., had all to be carefully and systematically regulated. Because of this imperative need for central control, linen and cotton printing works represent the beginnings of the factory system proper, for supervision is more the essence of the factory system than numbers of operatives, or quantities of machines employed. But it is a pity that at the end of the 18th century when William Hincks made his series of twelve engravings to illustrate various processes of the linen manufacture in Ireland, he did not also include some views of printers at work. The only idea of what the interior of Grimshaw’s printing department, for instance, may have looked like at all, has to be based on Rosetti’s series of wall-paintings of Wetter’s factory at Orange, in southern France. Those paintings were done about 1764 and Pl. III shows one scene, i.e. “pinceauteuses” engaged in painting additional details into fabrics by hand. Possibly in 1780 or so, a somewhat similar scene might have met the view of visitors to Greencastle.

3. WORKROOM of the “pinceauteuses” in Wetter’s factory at Orange, in Southern France.

Wall-painting by J. G. Rosetti, about 1764. (Photograph of original reproduced through CIBA, Basle.)

In conclusion I wish to acknowledge my indebtedness to all the following:- the authorities of CIBA Review (Basle) for permission to reproduce the photograph of one of Rosetti’s wall-paintings at Orange; Mr. C.E. Duffin for the photograph of Grimshaw’s portrait; Miss L. Duffin for the loan of the Grimshaw pedigree and for elucidating certain passages not given in full in the printed version of the Drennan Letters; my husband for drawing the map, and to the late Mr. Arthur Deane, Mr. A.H. George, and Mr. John Hewitt for help over several queries.

LIST OF LINEN, COTTON AND CALICO PRINTERS

IN NORTHERN IRELAND, ABOUT 1759-1800.

JAMES PETERS, Coleraine, c. 1759.

HUGH McCUTCHEON, Newtownards, c. 1771.

NICHOLAS GRIMSHAW, Greencastle, later at Whitehouse, 1776-1805.

Succeeded by his sons Edmund, Thomas and James Grimshaw, 1805.

RICHARD WILLIAMSON, Gilford, later at Annsborough, c. 1777-81.

JOY and CO., Falls, 1787-95.

PATRICK GAW and CO., Stonyford, c. 1787-88.

GEORGE McCAMON and CO., Stranmillis, c. 1793-97.

ABEL BROWN, Muckamore, 1795.

WILLIAM FARQUHAR, Milltown, Falls, 1796.

HENRY J. McCRACKEN, Knockairn, 1796.

GRAHAM and CO.,later AARON STANTON and CO., Carnmoney, c. 1796-1819.

WILLIAM HALL and CO., Woodburn, Carrickfergus, 1804-05.

REFERENCES

1. Jour. Roy. Soc. Ant. Ire. vol. 67 (1937) pp.26-56; vol. 75 (1945) pp.24-31; vol. 76 (1946) pp.13-15.

2. Printing on cotton not allowed in England till 1774; from 1736 to 1774 only on a mixed linen and cotton material. In France not officially allowed till 1759.

3. H.R. D’Allemagne, La toile imprimée et les indiennes de traite, Paris, 1948. H. Clouzot and F. Morris, Painted and Printed Fabrics, New York, 1927. F. Lewis, English Chintz, Leigh-on-Sea, 1942. MacIver Percival, The Chintz Book, New York, 1923. CIBA Review, No. 31, Textile Printing in 18th century France, Basle, 1940.

4. Dub. Gaz., 18th Aug., 1752. The factory was visited by the famous Mrs. Delany in Dec., 1752.

5. “The Drumcondra Company” is referred to as “now in great Prosperity near London” in Sandy’s petition of 1759. Ir. Ho. of Commons Journals, 6 Nov., 1759.

6. Univ. Advertiser, 15 March, 1757, etc

7. Ib., 25 Feb 1758; 10 June 1758.

8. Discovered and tested by Claude Berthollet and Samuel Widmer in France towards the end of the 18th century.

9. A solid background of colour with the pattern reserved in white was often referred to as a “field” colour.

10. Bel. N-L. 30 Apr 1771, etc.

11. Bankruptcy lists in London Gazette. H.R. D’Allemagne, La toile imprimée et les indiennes de traite, Paris, 1948, p.7.

12. London Gazette, 17 Aug 1771.